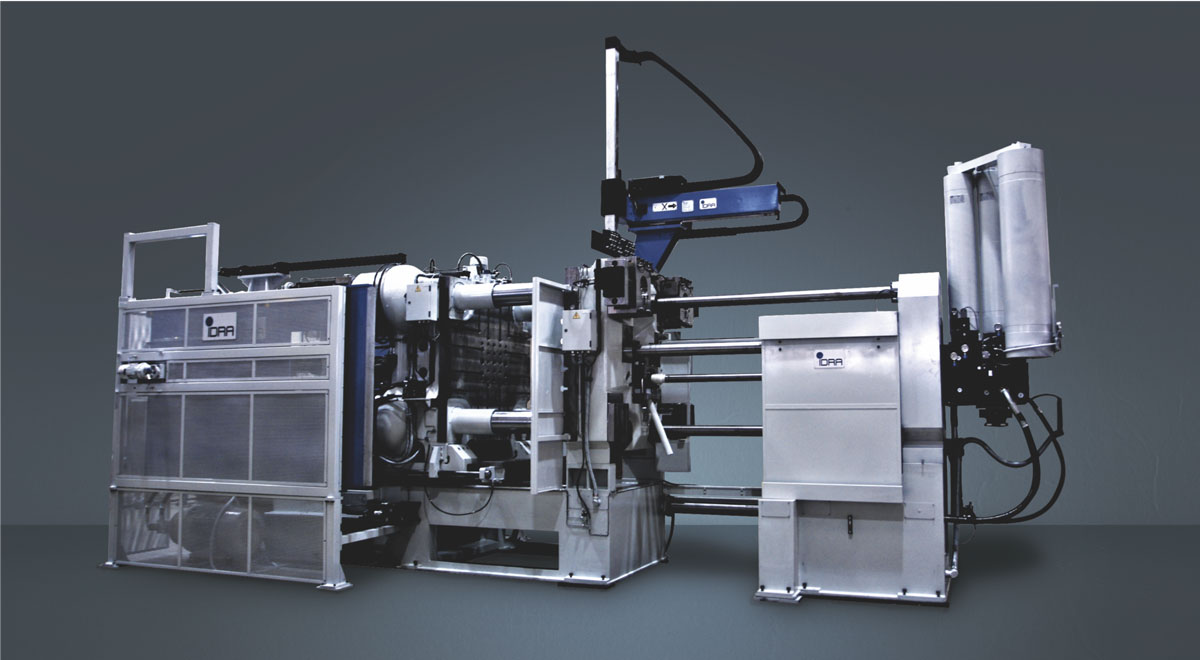

NOX - ZERO OXIDE PROCESS

It assumes no oxides, low hydrogen content, high density components.

In the automotive industry, high-performance castings are required for body and suspension elements.

The required values of ultimate strength, yield strength and elongation cannot be obtained by the traditional injection molding process.

NOX (ZERO OXIDE PROCESS)

-

ADVANCED TECH FOR STRUCTURAL COMPONENTS

-

DEEP VACUUM IN THE CAVITY

-

DOSAGE OF MELTED ALUMINUM IN A SECURITY ENVIRONMENT

-

NO AIR CONTACT

-

ACCURATE FILLING SPEED CONTROL

-

CAN BE INSTALLED ON DCM FROM 1300 TO 6200T

FORMS

-

LACK OF OXIDES

-

REDUCED HYDRAULIC CONTENT

-

HIGH DENSITY COMPONENTS

PROVIDING

-

LOW POISON

-

HIGH PLASTICITY

-

FITNESS FOR HT AND WELDING