Fire-resistant shaped products for the casting and metallurgical industry of SEEIF Ceramics

Shaped chamotte and high alumina products intended for casting metals, structural, construction and special applications, such as internal masonry, arches and other technological parts of metallurgical and thermal units.

The molded assortment consists of standardized bricks, plates, wedges, radial and various industrial shaped blocks. Machine-pressed blocks are made of various grades from pulp for semi-dry and dry pressing of raw material and from plastic masses.

SEEIF has extensive experience in the manufacture of refractory shaped products used in the foundry and metallurgical industries. You can get expert advice regarding the use of SEEIF products and their technical parameters from Kitmas specialists.

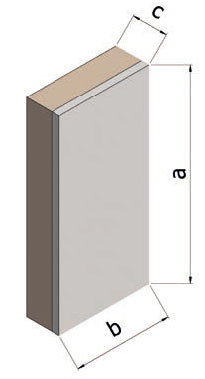

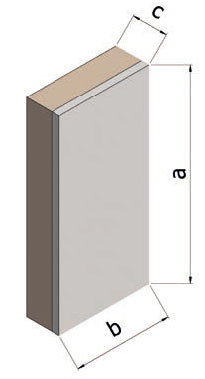

PLATES

|

|

Type

|

a (mm)

|

b (mm)

|

c (mm)

|

|

C25/35

|

250

|

123

|

35

|

|

C25/65

|

250

|

123

|

65

|

|

NF1

|

230

|

114

|

64

|

|

NF2

|

250

|

124

|

64

|

|

PLATES „BOOK“

|

|

Type

|

a (mm)

|

b (mm)

|

c (mm)

|

|

C25/35/Z

|

250

|

123

|

35

|

|

C25/65/Z

|

240

|

123

|

65

|

|

C25/85/Z

|

250

|

123

|

85

|

|

WEDGES E, N, Z

|

|

Type

|

a (mm)

|

b (mm)

|

c (mm)

|

d (mm)

|

|

E1

|

200

|

120

|

130

|

45

|

|

E2

|

300

|

120

|

130

|

45

|

|

E3

|

200

|

165

|

180

|

65

|

|

E4

|

300

|

165

|

180

|

65

|

|

E5

|

200

|

240

|

260

|

90

|

|

E6

|

300

|

240

|

260

|

90

|

|

E7

|

200

|

165

|

180

|

130

|

|

E8

|

300

|

165

|

180

|

130

|

|

E30-1/2

|

250

|

60

|

70

|

30

|

|

N30-2-1/2E

|

200

|

60

|

70

|

30

|

|

E45-1/2

|

250

|

80

|

90

|

45

|

|

N45-2-1/2E

|

200

|

60

|

70

|

45

|

|

E65

|

250

|

110

|

130

|

65

|

|

E65-2

|

200

|

110

|

130

|

65

|

|

E90

|

250

|

110

|

130

|

90

|

|

E90-2

|

200

|

110

|

130

|

90

|

|

|

Type

|

a (mm)

|

b (mm)

|

c (mm)

|

d (mm)

|

|

Z1

|

200

|

117

|

123

|

30

|

|

Z2

|

300

|

117

|

123

|

30

|

|

Z3

|

200

|

117

|

127

|

45

|

|

Z4

|

300

|

117

|

127

|

45

|

|

Z5

|

200

|

148

|

165

|

65

|

|

Z6

|

300

|

148

|

165

|

65

|

|

Z7

|

300

|

250

|

270

|

75

|

|

Z8

|

400

|

250

|

270

|

75

|

|

Z9

|

300

|

250

|

270

|

95

|

|

Z10

|

400

|

250

|

270

|

95

|

|

Z11

|

300

|

250

|

270

|

120

|

|

Z12

|

400

|

250

|

270

|

120

|

|

Z13

|

300

|

200

|

260

|

160

|

|

Z14

|

300

|

200

|

260

|

180

|

|

M WEDGES

|

|

Type

|

a (mm)

|

b (mm)

|

c (mm)

|

d (mm)

|

|

K10

|

250

|

60

|

70

|

123

|

|

M65

|

250

|

95

|

115

|

65

|

|

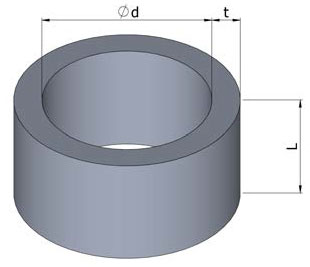

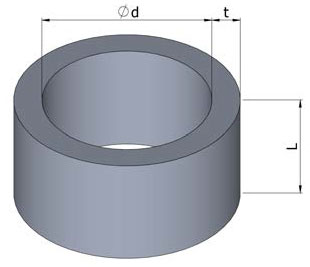

ROUND BANDAGES

|

|

Type

|

t (mm)

|

d (mm)

|

L (mm)

|

|

B80/100

|

20

|

80

|

100

|

|

B100/100

|

25

|

100

|

100

|

|

B120/100

|

20

|

120

|

100

|

|

B150/100

|

30

|

150

|

100

|

|

B180/100

|

30

|

180

|

100

|

|

B210/100

|

30

|

210

|

100

|

|

B240/100

|

30

|

240

|

100

|

|

B180/150

|

30

|

180

|

150

|

|

B210/150

|

30

|

210

|

150

|

|

B300/100

|

35

|

300

|

100

|

|

B400/150

|

65

|

400

|

150

|

|

IZOCAST - INSULATION OF CASTINGS

IZOCAST sandwich double-layer insulated shaped blocks are used in foundries when it is necessary to increase the length of the supply line at a given casting site or to extend the solidification time. Shaped blocks are placed primarily on the surface, where it is necessary to extend the solidification time without affecting the surface quality negatively - this applies to surface areas that will not be subjected to further machining or with only a small allowance for processing.

- prolongs the solidification time, increases the length of the supply line in the desired casting places

- without additional processing - thanks to a special working layer. Places where IZOCAST products were used, after their removal do not require further processing and cleaning

- simple machining - blocks can be easily cut and customized directly in place to the required dimensions

|

|

Type

|

a (mm)

|

b (mm)

|

c (mm)

|

|

IZOCAST 40

|

245

|

123

|

40

|

|

IZOCAST 60

|

245

|

123

|

64

|

|