OL R - TWO PLATEN TOGGLE FREE MACHIN

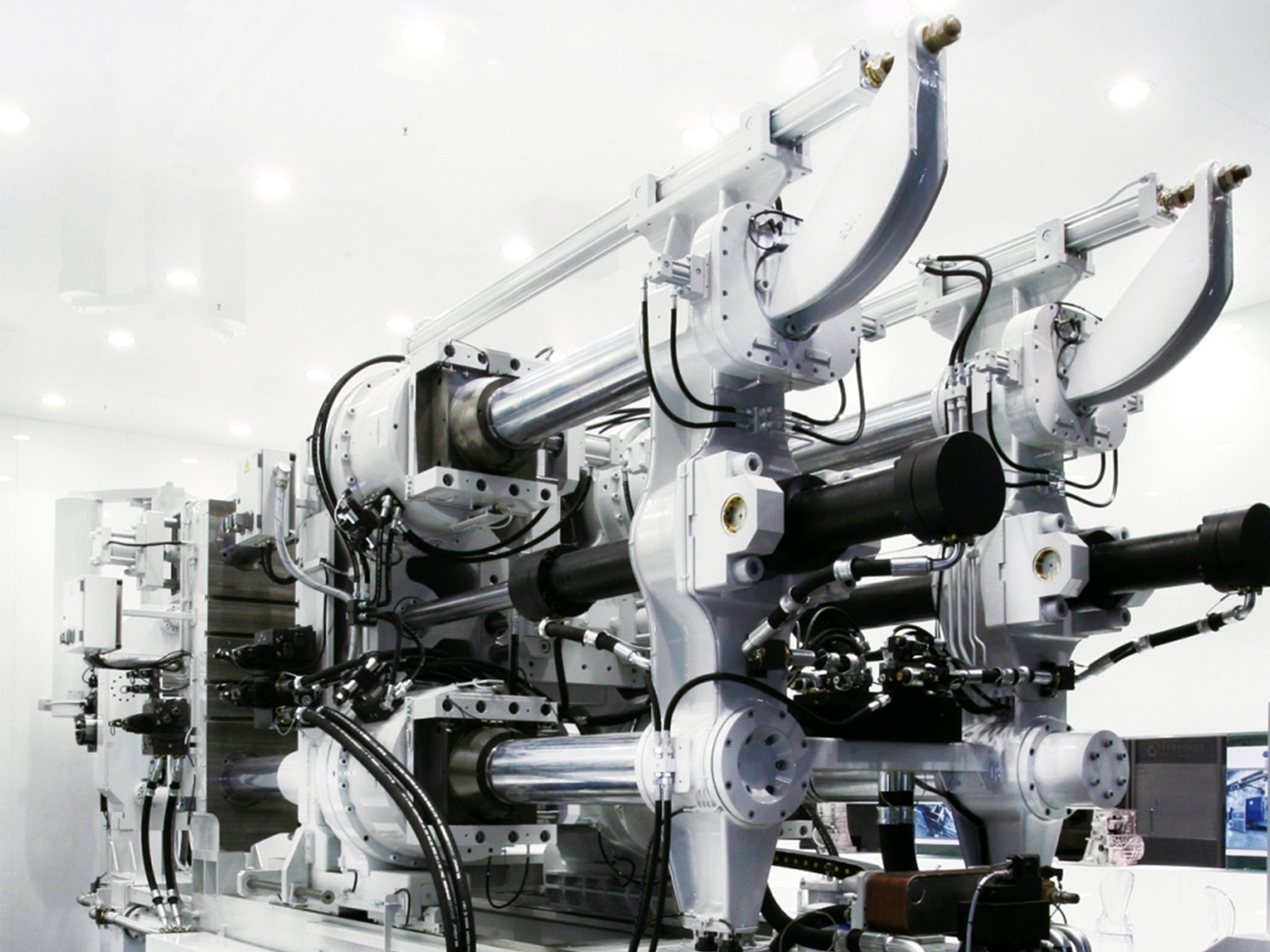

OL R machines are a new generation of presses with shorter lengths compared to similar models and better load distribution.

ПЕРЕВАГИ СЕРІЇ ПРЕСІВ OL R:

- COMPACT 2 TABLET HPDC

- 1000 T to 4600 T

- LARGE SIZE PLATES

- COMPACT SIZE

- CONTROLLER COMPUTER IC 3.0

- HMI AWARDS

- BUILT-IN HYDRAULIC COLLECTOR

- CLOSED INJECTION SYSTEMS

Shortening the length of the machine compared to similar models and the automatic distribution of load on the crossbar, automatically compensate for thermal expansion, are the most significant advantages.

The clamp offers large plate sizes that exceed standard models and makes the R Series the best machine for producing structural members as well as for very large dies.

Closed loop real-time injection control and Idra Bicostant intensification pressure control provide outstanding performance in terms of injection rate, response time and parameter consistency, as well as all the basic requirements for high integrity casting.

The R Series was designed with integrated, modular and compact hydraulic manifolds with very few external pipes to eliminate fluid leakage and facilitate maintenance. The machine is environmentally friendly and has low power consumption, since in the standard configuration it is equipped with controlled motors with frequency variators (inverters).

R-series machines can be supplied as standard, as well as in the NOX design, with a built-in furnace to withstand the transfer of metal into the injected sleeve, avoiding any contact with the atmosphere and subsequent oxidation of the metal.